Design & Engineering

Design Capabilities

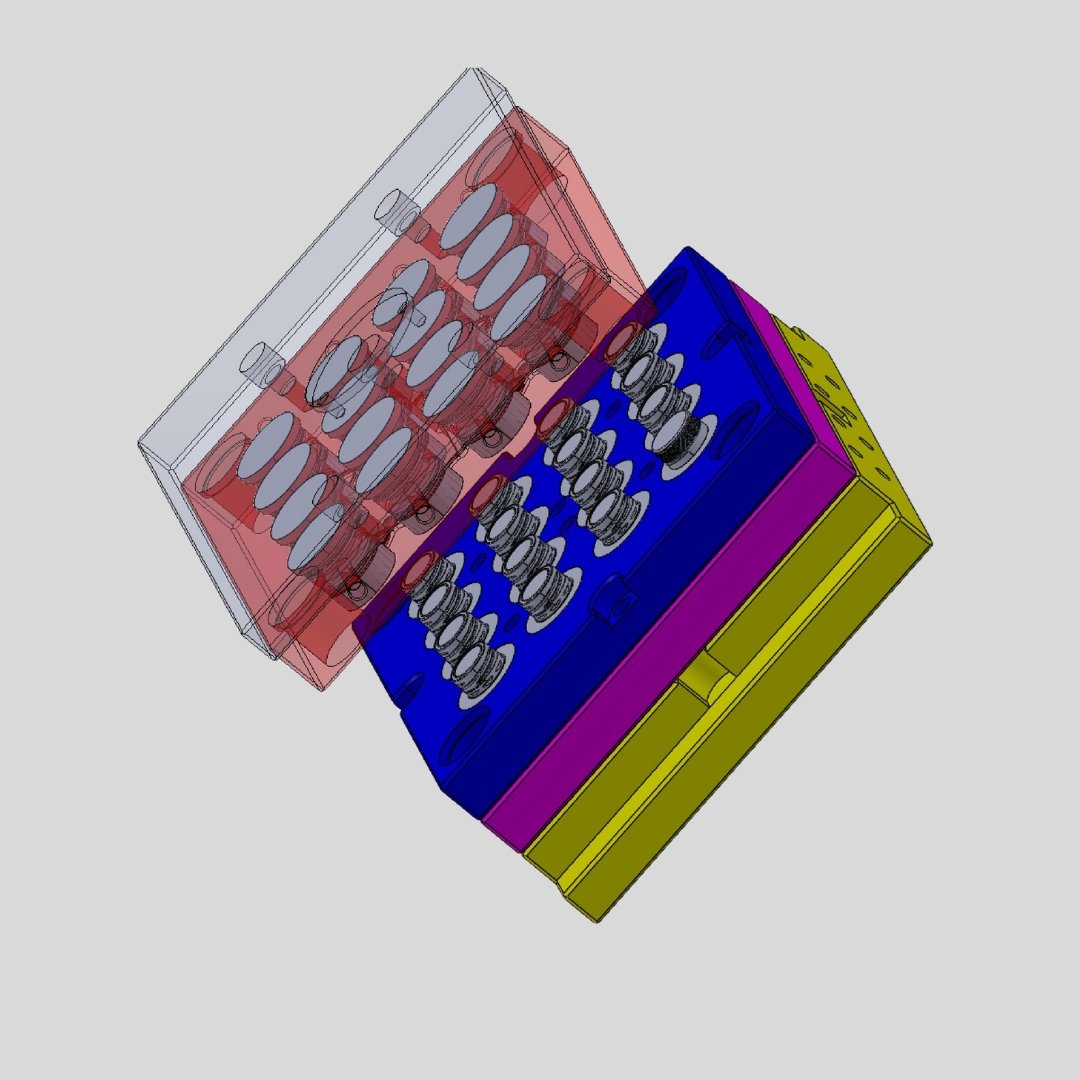

Dedicated to achieving excellence in product quality, Royalmoldsanddies employs cutting-edge software for product design and molding processes. Our commitment to innovation is evident in the establishment of our advanced (SOLIDWORKS,UNIGRAPHIC AND AUTO CAD), equipped with state-of-the-art software to facilitate precise product development.

Harnessing high levels of expertise, Royalmoldsanddies ensures the production of products with uniform dimensions, setting us apart in the industry. Our investment in the latest software extends to quality-driven product design, mold design, and molding process simulations. Through this advanced design methodology, we guarantee optimal product features such as thickness, thread fitment, stretchability, weight, and more.

Design Capabilities

One of the cornerstones of our approach to product development is the integration of advanced software solutions into our design and manufacturing processes. From initial product conceptualization to final production, Royalmoldsanddies employs the latest software technologies to optimize every stage of the process. This includes utilizing cutting-edge software for product design, mold design, and comprehensive molding process simulations.

By adopting this advanced design methodology, we can guarantee not only the optimal dimensions of our products but also the refinement of essential product features such as thickness, thread fitment, stretchability, weight, and more. This meticulous approach to product development ensures that each product manufactured by Royalmoldsanddies meets the exacting standards of quality and performance expected by our customers.

At Royalmoldsanddies, innovation is more than just a buzzword; it’s a fundamental principle that drives everything we do. By continuously investing in the latest software technologies and refining our processes, we remain at the forefront of the industry, delivering best-in-class products that exceed expectations.

The in-house design studio at Royalmoldsanddies performs processes of Product design, mold analysis, mold design and mold process simulation thereby producing a finely engineered product for the end users.

At Royalmoldsanddies, our dedication to innovation is embodied in our cutting-edge Research & Development (R&D) center. Here, we’ve spared no expense in equipping our facility with state-of-the-art CAD/CAM/CAE workstations, empowering our team to engage in high-end work processes that drive progress and excellence.

Our R&D center serves as the beating heart of our operations, where ideas are transformed into reality through meticulous planning and precision engineering. With advanced CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CAE (Computer-Aided Engineering) capabilities at our fingertips, we’re able to push the boundaries of what’s possible in product development and manufacturing.

From conceptualization to prototyping and beyond, our team leverages these advanced tools to streamline workflows, optimize designs, and enhance efficiency at every stage of the process. Whether it’s designing intricate mold components or simulating complex manufacturing processes, our CAD/CAM/CAE workstations are essential tools in our pursuit of excellence.

But our R&D center is more than just a facility—it’s a hub of creativity and innovation, where ideas are nurtured and breakthroughs are celebrated. It’s where we collaborate, experiment, and push the limits of what’s possible, all in the name of delivering unparalleled quality and value to our customers.